Meyer Burger develops solar technology – from wafers to solar PV systems – with the aim of promoting the widespread use of photovoltaics energy and making solar power a first-choice source of renewable energy. To this end, the company focuses strongly on developing robust solar technology that is highly efficient, long lasting, and reliable. For the past twenty years, the topic of the inter face between the cell and the module has been largely ignored. Today, high-efficiency solar cells such as heterojunction technology (HJT) (with efficiency of 25.6%, as demonstrated in 2014 by Panasonic [1]), the selective emitter, rear passivated cells, or interdigitated back-contact technology (IBC) require special care, as the loss during photo-generated current transportation should be reduced without sacrificing solar module reliability. Meyer Burger develops the wire bonding technology, known as SmartWire Connection Technology (SWCT), with the aim of transforming high-efficiency solar cells into reliable modules while minimizing the cell-to-module loss and cost.

Introduction

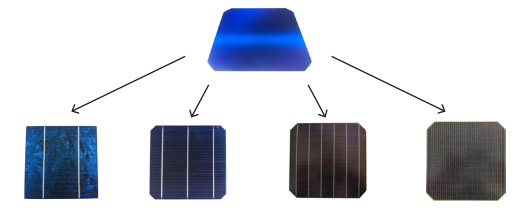

Evolution of cell front side appearance, from left to right

The technology transforms the appearance of the front cell surface as presented in Figure 1 and offers additionally several benefits:

By bonding multiple wires, ohmic losses and/ or finger thickness can be limited, as the num- ber of wires can be adapted to the specific cell design

Since busbars and the back side Ag are not needed in these cell structures, silver paste consumption can be significantly reduced

As a result of the wires› light reflection, light coupling into the module can be improved when SWCT is ap- plied

SWCT reduces the impact of cell breakage by increasing the number of current collection pathways

The process steps are simplified as the soldering and the lami- nation processes are coupled

The technology reduces stress on the wafer, as the temperature during the connection process step is homogenous and kept below 160°C

Total cost of ownership is lower as a result of silver paste con- tent of less than 2.4 g per 60-cell module with screen printing technology or even without silver in the case of Cu plating tech- nology

The technology reduces stress on the wafer, as the temperature during the connection process step is homogenous and kept below 160°C

SWCT is compatible with multiple material types such as Al, Cu, Ni, and Ag and therefore opens the door to new material combinations and the interconnection of new cell concepts, such as rear passivated cells, HJT cells, IBC cells and cells implementing metal plating.