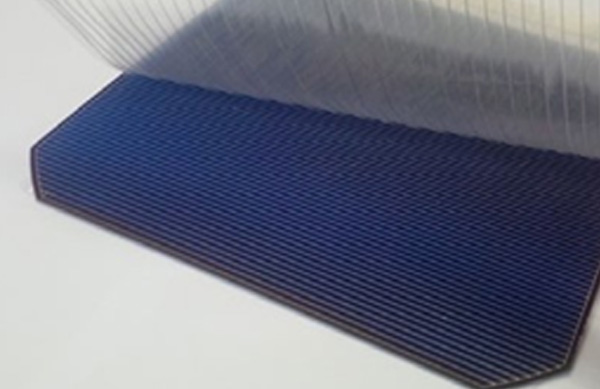

SWCT is a solar cell interconnection technology based on wire bonding. Typically, between 15 and 38 wires are used on both sides of the solar cell. The wires are round Cu-based wires coated with a low melting-point alloy, generally an alloy layer of 3-5 μm in thickness with 50% Indium (Figure 2). The wires are embedded in a polymer foil that is applied directly onto the metallized cell (Figure 3). The stack is then laminated together. The wires are bonded to the metallization of the cell and provide electrical contact to the metals (e.g. Cu, Ag, Al, Ni, and their alloys). The number of wires and their thickness can be customized to match almost any cell metallization design or cell power class. It should be noted that busbars on the cell surface (both on the front and back side) are not needed. This will save material costs (especially if the metallization scheme requires expensive material, such as silver paste) and pre- vent unnecessary shading. SWCT has the added benefit that better cell backside passivation can be achieved with either a full area Al screen-printed back surface field, or with any backside dielectric passivation concept, such as SiO, a-Si, AlOX. This is because high temperature soldering steps can be avoided and the constraint be- tween the wire and metallization is relaxed.