The reliability and outdoor performance of a PV module is one of the end user’s biggest concerns because the in- vestment is a medium to long term investment and there- fore has to last over the years. Even the highest-efficiency module needs to last 20 to 40 years in outdoor condi- tions. Here, extended climatic chamber tests required for IEC certification, damp heat (DH, 85% relative humidity, 85°C) and thermal cycling (TC, -40°C to 85°C in 6 hours) are presented. Damp heat is critical for the encapsulation material and the cell technology, whereas thermal cycling is vital when it comes to the reliability of interconnection technology.

Module reliability

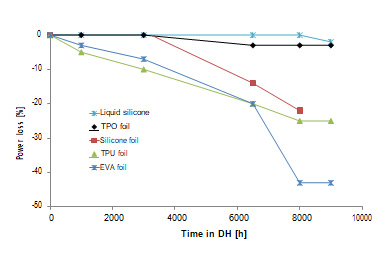

Standard module design comprises an EVA encapsula- tion layer and a PET or PET-Tedlar based back sheet. This sandwich has the disadvantage of degradation when modules are exposed to moisture. This effect is shown in Figure 10, where power loss data from solar modules made with standard c-Si cells and encapsulated with ma- terials such as TPU, TPO and EVA were collected. The cells are diffused cells used in our module production in Switzerland (Thun). A strong power loss in damp heat con- ditions for a module with EVA was observed. This power degradation occurring between 2000 and 6000 hours of DH for modules encapsulated with EVA material is classic, as shown in the following publications [7,8]. The EVA quality is usually the main criterion for the timing of the deg- radation. The superior performance of liquid silicone and TPO compared with EVA is shown in Figure 10. The liq- uid silicone and TPO encapsulant absorbed less moisture than EVA. Both of these materials offer protection against potential induced degradation (PID), as described in [7]. TPO has been chosen as the current solution for SWCT as it provides a more reliable performance and is available as a foil at a low cost. This TPO material provides also a per- fect combination with HJT cells since we do not observe any degradation up to 5000 h in damp heat.

Figure 10: Mini-module performance following damp heat exposure. The modules were encapsulated with various materials and using standard c-Si cells metallized with a high-temperature Ag paste)

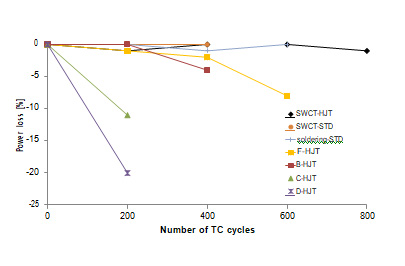

The critical test for the interconnection technology is the thermal cycling test. Figure 11 presents the results of mini- modules based on HJT and standard cells that were con- nected with various technologies. SWCT provided excel- lent resistance to thermal cycling test conditions, as no power degradation was observed on HJT modules follow- ing more than 800 cycles (four times the IEC criteria). This clearly demonstrates the superior performance of SWCT compared to other connecting technologies even for low- temperature Ag paste metallization scheme. SWCT pro- vide also excellent durability for standard cell with up to 400 cycles without losses. The modules will remain in the chamber until a failure appears.

Figure 11: Performance loss of SWCT modules after ther- mal cycling compared to other connection technologies. Both HJT and standard (STD) c-Si solar modules are pre- sented here