Smartwire connection technology

Higher module power output

Increased module power performance of up to 6%

compared to 3-busbar technology

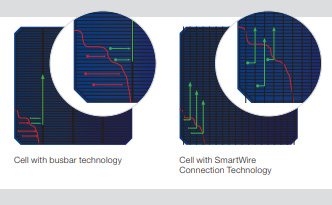

Dense contact matrix connecting points on the solar cell

Less electrical resistivity and thus less power dissipation

Less impact from optical shading

Improved light reflection with round SWCT wire design.

Higher tolerance to cell micro cracks

Elimination of busbar printing increases solar cell active area

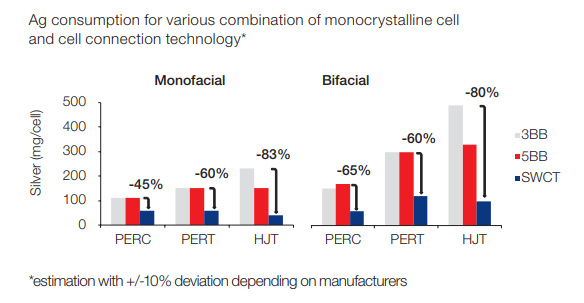

Less silver consumption in cell production

Solar cells connected with SWCT can achieve a reduction up to 83% of silver consumption in cell production

No front busbars, no silver pads on the back-side

Multiple wires allow thinner and more resistive fingers with lower aspect ratios

Bifacial technology compatible

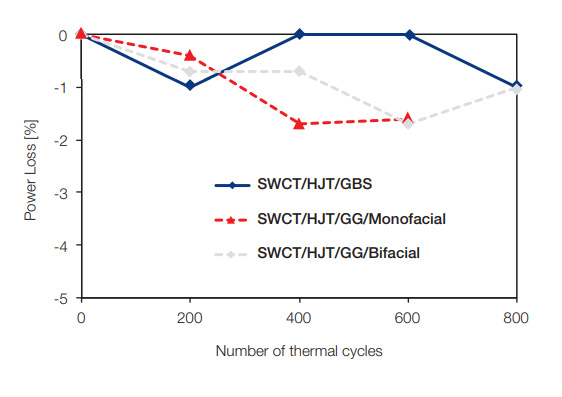

Reliable modules with higher energyyield

Successful IEC and UL certification tests (extended damp heat and thermal cycling passed)

Reduced stress on the wafer as bonding of wires takes place at temperatures below 160°C

Long lasting PV modules enabled with low water absorption encapsulation materials

Gain in energy yield of over 15% under outdoor conditions

Bi-facial SWCT modules show an increased energy yield in terms of kWh/Wp under real outdoor conditions compared with mono-facial modules.

More energy on smaller systems at lower BOS investment costs